- Description

- Contact Us

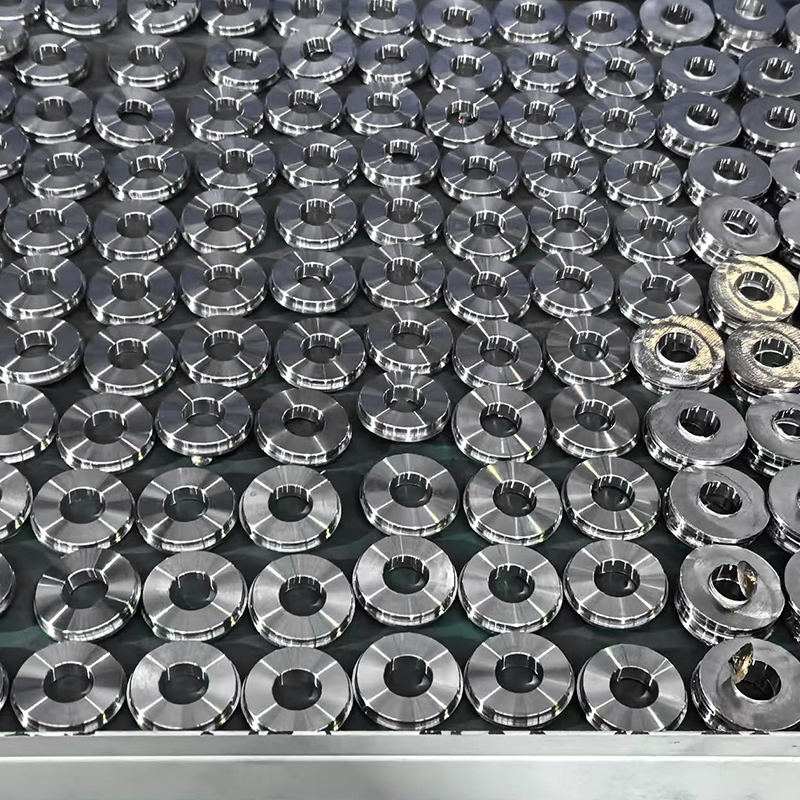

Thrust Plates (Coated Thrust Plates) are widely used in various types of machinery, such as pumps, bearings, and motors. Their primary function is to withstand axial loads, and through specialized structural design and material treatment, they help enhance operational efficiency and extend service life.

Basic Functions and Structure of Thrust Plates

The main role of a thrust plate is to bear axial forces while providing protection to bearings and sealing components through a lubricating film, thereby reducing wear and improving the efficiency of the equipment. For example, in magnetic drive pumps, the thrust plate forms an extremely thin liquid film that balances and absorbs axial forces, protecting both bearings and seals. A typical thrust plate consists of several key components, including the thrust seat, thrust bearing, screws, and mating plate.

Coated thrust plates utilize surface coating technology to enhance performance and are widely applied in high-speed thrust bearings used in aerospace and automotive systems. These coatings effectively extend equipment life and improve operational stability.

Our company can provide related pump parts such as pump shafts, shaft sleeves, thrust plates, rings, wear-resistant rings, rotors, and other related pump parts. It is mainly used in shielding pumps, centrifugal pumps, mud pumps, rotor pumps, etc.

The above pump parts support customers to draw up processing.

Material:

We can use specified metal materials to make related parts of such pumps, such as stainless steel, 304, 316/316L, Sitai alloy, etc.

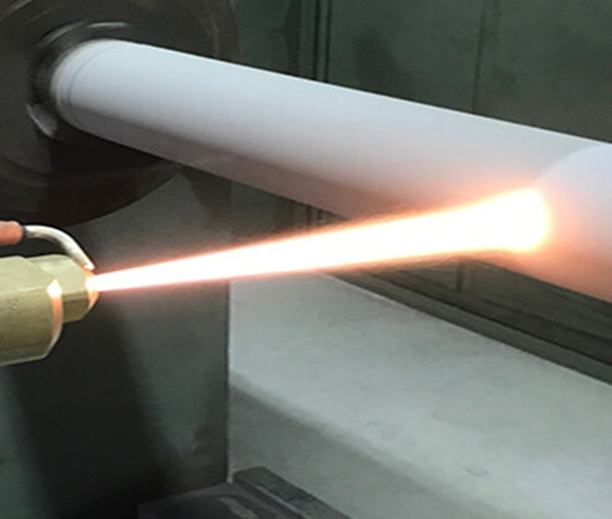

All of our pump parts can meet all your pump transmission needs, and provide ceramic and tungsten carbide surface coating to apply to abrasion, corrosive, and high-temperature applications.

Welcome To The Professional Manufacturer Of Thermal Spraying.

Share With You

-

12 Feb 2026

12 Feb 2026Thermal Spray Coatings Guide: HVOF, Ceramic, and Tungsten Carbide Coating Solutions

What Is Thermal Spray and How Does the Process Work? Thermal spray is a group of industrial coating processes in which feedstock materials — supplied as powder,...

-

04 Feb 2026

04 Feb 2026Tungsten Carbide Coating Process: Complete Guide to Application Methods & Benefits

Understanding Tungsten Carbide Coatings Tungsten carbide coatings represent one of the most effective solutions for enhancing surface hardness, wear resistance,...

-

30 Jan 2026

30 Jan 2026What Is Abrasion Resistant Coating and When Should You Use It?

Understanding Abrasion Resistant Coating and Its Core Purpose Abrasion resistant coating is a surface treatment designed to protect substrates from mechanical w...

-

21 Jan 2026

21 Jan 2026Techniques and Materials Used in Ceramic Thermal Spray Coatings

Overview of Ceramic Thermal Spray Coatings Ceramic thermal spray coatings are advanced surface engineering solutions applied to protect metal, ceramic, or compo...

TOP

TOP

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体