- Description

- Contact Us

Axial sleeve (Coating Shaft Sleeve) is a mechanical component that is usually used to protect the surface of the rotating shaft from wear, corrosion, and damage caused by contact with other parts. This sleeve is usually installed between the rotating shaft and the bearing and is one of the important components of the sliding bearing.

The main functions of the axial sleeve include:

Protecting the shaft surface: The axial sleeve extends the service life of the shaft by reducing friction and wear. For example, it can prevent scratches or grooves caused by contact with hard materials.

Sealing effect: The axial sleeve can be used in conjunction with seals to prevent gas leakage or liquid leakage, thereby improving the overall operating efficiency of the equipment.

Wear resistance: The axial sleeve is made of wear-resistant materials to meet the needs of high-load and high-speed environments.

Low replacement cost: When the axial sleeve is worn, it can be replaced separately without replacing the entire shaft, thereby reducing maintenance costs.

Our company can provide related pump parts such as pump shafts, shaft sleeves, thrust plates, rings, wear-resistant rings, rotors, and other related pump parts. It is mainly used in shielding pumps, centrifugal pumps, mud pumps, rotor pumps, etc.

The above pump parts support customers to draw up processing.

Material:

We can use specified metal materials to make related parts of such pumps, such as stainless steel, 304, 316/316L, Stellite alloy, etc.

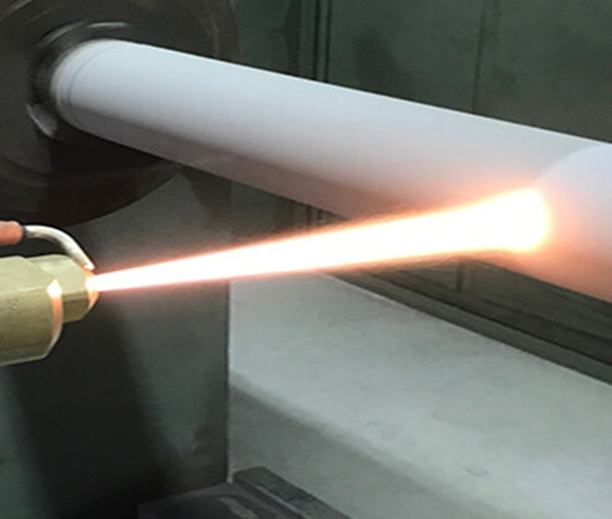

All of our pump parts can meet all your pump transmission needs, and provide ceramic and tungsten carbide surface coating to apply to abrasion, corrosive, and high-temperature applications.

Welcome To The Professional Manufacturer Of Thermal Spraying.

Share With You

-

12 Feb 2026

12 Feb 2026Thermal Spray Coatings Guide: HVOF, Ceramic, and Tungsten Carbide Coating Solutions

What Is Thermal Spray and How Does the Process Work? Thermal spray is a group of industrial coating processes in which feedstock materials — supplied as powder,...

-

04 Feb 2026

04 Feb 2026Tungsten Carbide Coating Process: Complete Guide to Application Methods & Benefits

Understanding Tungsten Carbide Coatings Tungsten carbide coatings represent one of the most effective solutions for enhancing surface hardness, wear resistance,...

-

30 Jan 2026

30 Jan 2026What Is Abrasion Resistant Coating and When Should You Use It?

Understanding Abrasion Resistant Coating and Its Core Purpose Abrasion resistant coating is a surface treatment designed to protect substrates from mechanical w...

-

21 Jan 2026

21 Jan 2026Techniques and Materials Used in Ceramic Thermal Spray Coatings

Overview of Ceramic Thermal Spray Coatings Ceramic thermal spray coatings are advanced surface engineering solutions applied to protect metal, ceramic, or compo...

TOP

TOP

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体