- Description

- Contact Us

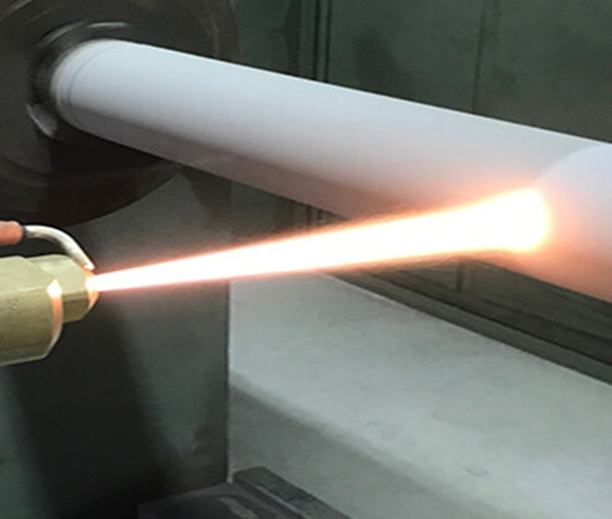

The Imodium Wear-Resistant Ring is a high-performance industrial component designed for extreme durability in abrasive and corrosive environments. Engineered with advanced materials and specialized coatings, it ensures long-lasting performance with minimal wear, even under harsh operating conditions.

Superior Wear Resistance – Built to withstand high friction and mechanical stress, reducing downtime and maintenance costs.

Corrosion Protection – Resistant to chemicals, acids, and oxidation, making it ideal for aggressive industrial applications.

High-Temperature Stability – Maintains structural integrity in elevated temperatures, ensuring reliable operation.

Precision Engineering – Manufactured to tight tolerances for consistent performance in demanding machinery.

Customizable Options – Available in various sizes, materials, and coatings to meet specific application requirements.

Applications

Pump & Valve Seals – Extends service life in fluid handling systems.

Industrial Machinery – Protects rotating and sliding components from wear.

Chemical Processing – Resists degradation from corrosive substances.

Heavy Equipment – Enhances durability in mining, oil & gas, and manufacturing.

Our company can provide related pump parts such as pump shafts, shaft sleeves, thrust plates, rings, wear-resistant rings, rotors, and other related pump parts. It is mainly used in shielding pumps, centrifugal pumps, mud pumps, rotor pumps, etc.

The above pump parts support customers to draw up processing.

Material:

We can use specified metal materials to make related parts of such pumps, such as stainless steel, 304, 316/316L, Sitai alloy, etc.

All of our pump parts can meet all your pump transmission needs, and provide ceramic and tungsten carbide surface coating to apply to abrasion, corrosive, and high-temperature applications.

Welcome To The Professional Manufacturer Of Thermal Spraying.

Share With You

-

12 Feb 2026

12 Feb 2026Thermal Spray Coatings Guide: HVOF, Ceramic, and Tungsten Carbide Coating Solutions

What Is Thermal Spray and How Does the Process Work? Thermal spray is a group of industrial coating processes in which feedstock materials — supplied as powder,...

-

04 Feb 2026

04 Feb 2026Tungsten Carbide Coating Process: Complete Guide to Application Methods & Benefits

Understanding Tungsten Carbide Coatings Tungsten carbide coatings represent one of the most effective solutions for enhancing surface hardness, wear resistance,...

-

30 Jan 2026

30 Jan 2026What Is Abrasion Resistant Coating and When Should You Use It?

Understanding Abrasion Resistant Coating and Its Core Purpose Abrasion resistant coating is a surface treatment designed to protect substrates from mechanical w...

-

21 Jan 2026

21 Jan 2026Techniques and Materials Used in Ceramic Thermal Spray Coatings

Overview of Ceramic Thermal Spray Coatings Ceramic thermal spray coatings are advanced surface engineering solutions applied to protect metal, ceramic, or compo...

TOP

TOP

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体