- Description

- Contact Us

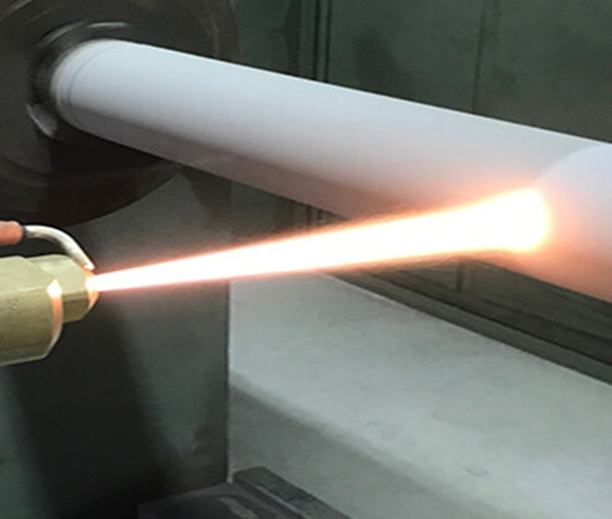

The mixing shaft, paddle, dispersion disc, mixing barrel, and other mixing equipment parts will constantly rub and collide with powder or other materials during mixing, which is easy to cause wear. By supersonic spraying of tungsten carbide coating, the surface hardness and good wear resistance of parts are improved, which can withstand the wear of high-speed operation and high-temperature friction. At the same time, it can also improve the corrosion resistance and oxidation resistance of parts, and can effectively protect parts from corrosion and oxidation.

Related technical parameters:

Coating series: tungsten alloy, nickel alloy, ceramic oxide

Coating hardness: above HRC70,

Coating thickness: 0.10-0.35mm controllable

Coating roughness: about Ra3.2, and polishing and grinding can also be performed to improve the surface finish.

Welcome To The Professional Manufacturer Of Thermal Spraying.

Share With You

-

12 Feb 2026

12 Feb 2026Thermal Spray Coatings Guide: HVOF, Ceramic, and Tungsten Carbide Coating Solutions

What Is Thermal Spray and How Does the Process Work? Thermal spray is a group of industrial coating processes in which feedstock materials — supplied as powder,...

-

04 Feb 2026

04 Feb 2026Tungsten Carbide Coating Process: Complete Guide to Application Methods & Benefits

Understanding Tungsten Carbide Coatings Tungsten carbide coatings represent one of the most effective solutions for enhancing surface hardness, wear resistance,...

-

30 Jan 2026

30 Jan 2026What Is Abrasion Resistant Coating and When Should You Use It?

Understanding Abrasion Resistant Coating and Its Core Purpose Abrasion resistant coating is a surface treatment designed to protect substrates from mechanical w...

-

21 Jan 2026

21 Jan 2026Techniques and Materials Used in Ceramic Thermal Spray Coatings

Overview of Ceramic Thermal Spray Coatings Ceramic thermal spray coatings are advanced surface engineering solutions applied to protect metal, ceramic, or compo...

TOP

TOP

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体