- Description

- Contact Us

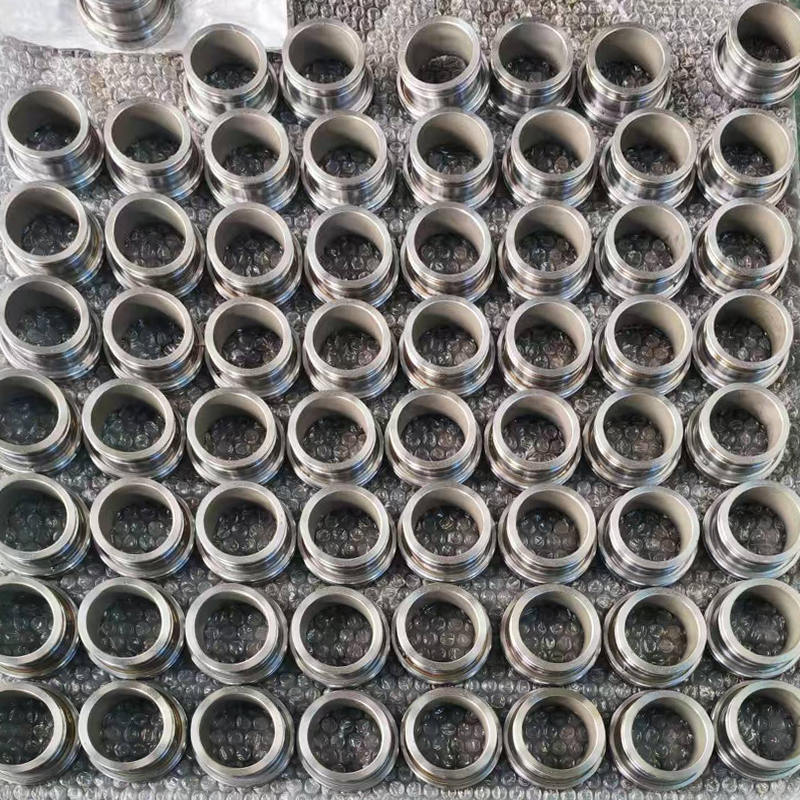

The Exhaust Valve is a critical component used in internal combustion engines to control the expulsion of exhaust gases from the combustion chamber. Designed for high-performance applications, it is engineered to withstand extreme temperatures, pressure variations, and chemical exposure while ensuring optimal engine efficiency and reliability.

The valve’s design includes precise sealing surfaces that facilitate proper valve seating and gas flow, helping to maintain engine efficiency, reduce emissions, and improve overall performance. Exhaust valves are available in various sizes and configurations, suitable for different engine types and specifications.

Coating materials: Ni, Co-based alloy powder, tungsten carbide powder, etc.

Process method: vacuum remelting surfacing, flame spraying

Our company adds high alloy elements to the original parent material and adopts vacuum remelting surfacing or thermal spraying technology to ensure that the high-temperature resistant alloy of the valve surface surfacing is fused with the parent material, without pores, slag inclusions, looseness, and other welding defects. High-temperature rolling can easily change the surfacing metallographic structure, making it more compact and refined, with higher hardness, greatly improving the high-temperature resistance and corrosion resistance.

Service: Support customized drawings

Welcome To The Professional Manufacturer Of Thermal Spraying.

Share With You

-

21 Jan 2026

21 Jan 2026Techniques and Materials Used in Ceramic Thermal Spray Coatings

Overview of Ceramic Thermal Spray Coatings Ceramic thermal spray coatings are advanced surface engineering solutions applied to protect metal, ceramic, or compo...

-

14 Jan 2026

14 Jan 2026What Is a Coated Shaft Sleeve and Why It Matters in Industrial Equipment

Understanding the Function of a Coated Shaft Sleeve A coated shaft sleeve is a protective cylindrical component installed over a rotating shaft to shield it fro...

-

07 Jan 2026

07 Jan 2026Abrasion Resistant Coating Basics Materials Performance and Uses

Understanding Abrasion Resistant Coating Fundamentals Abrasion resistant coating refers to a category of surface protection materials designed to reduce materia...

-

04 Jan 2026

04 Jan 2026Wear-Resistant Bushings vs Standard Bushings: What You Should Know

Introduction to Bushings Bushings are essential components in machinery, providing a bearing surface for rotary or sliding applications. They reduce friction, a...

TOP

TOP

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体