- Description

- Contact Us

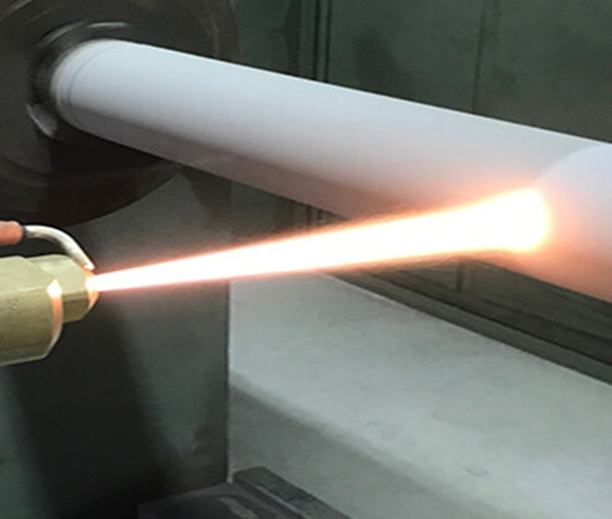

The Rotor Axis (Coating Rotor Axis) is a crucial component in coating equipment, designed to ensure stability and consistency in coating processes. With a precise structural design, it effectively manages rotation speed and load-bearing capacity, optimizing production efficiency and coating quality.

The Rotor Axis is used in coating machinery as a central part of the transfer and application of coating materials. It is typically made from high-strength alloy materials, ensuring stable operation under high loads and temperatures. The component's design enhances both the efficiency of the equipment and its service life. In various coating processes, the Rotor Axis contributes significantly to improving coating uniformity and adhesion, making it an essential factor for achieving high-quality results.

Our company can provide gear pump parts, such as gear pump sales, rotor shafts, bands, etc.

Material:

Stainless steel, such as 304, 316, and 316L stainless steel, has excellent corrosion resistance and strength and is suitable for application scenarios that require high corrosion resistance. Carbon steels such as 45 steel, 40Cr 20CRMNTI, etc. are often used in occasions that require higher strength and abrasion resistance.

Support customers to customize finished products with carbon-containing tungsten metal coating, nickel-based cobalt-based alloy coating, and oxide ceramic coating.

Welcome To The Professional Manufacturer Of Thermal Spraying.

Share With You

-

19 Feb 2026

19 Feb 2026Abrasion Resistant & Corrosion Resistant Coatings for Wear-Resistant Bushings and Plungers

Understanding Abrasion Resistant and Corrosion Resistant Coatings Abrasion resistant coatings and corrosion resistant coatings are two of the most critical surf...

-

12 Feb 2026

12 Feb 2026Thermal Spray Coatings Guide: HVOF, Ceramic, and Tungsten Carbide Coating Solutions

What Is Thermal Spray and How Does the Process Work? Thermal spray is a group of industrial coating processes in which feedstock materials — supplied as powder,...

-

04 Feb 2026

04 Feb 2026Tungsten Carbide Coating Process: Complete Guide to Application Methods & Benefits

Understanding Tungsten Carbide Coatings Tungsten carbide coatings represent one of the most effective solutions for enhancing surface hardness, wear resistance,...

-

30 Jan 2026

30 Jan 2026What Is Abrasion Resistant Coating and When Should You Use It?

Understanding Abrasion Resistant Coating and Its Core Purpose Abrasion resistant coating is a surface treatment designed to protect substrates from mechanical w...

TOP

TOP

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体