- Description

- Contact Us

The injection punch is one of the accessories and consumables of the die-casting machine. The quality of the injection punch (plunger head) directly affects the quality of the die-casting and the cost of die-casting production.

Existing problems: high contact temperature, about 680℃; the punch is not wear-resistant and has a short service life; poor product quality and damage to the barrel.

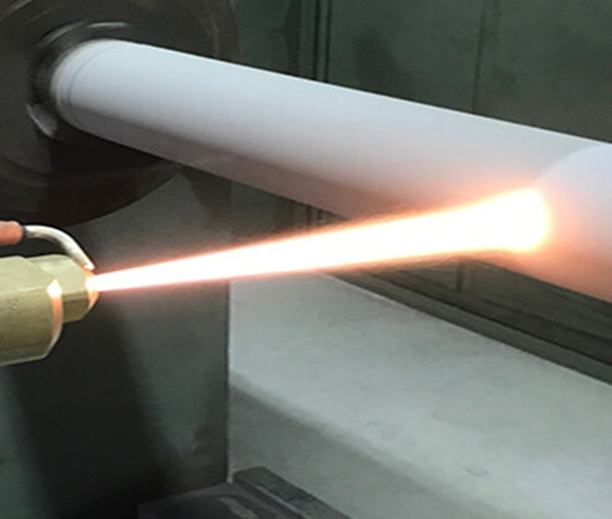

Solution: Spray a layer of hard material to achieve the following three effects: wear resistance, high-temperature resistance, and aluminum liquid corrosion resistance

Processing technology: Use advanced Japanese automated high-temperature isostatic pressing coating technology to melt-spray nano-alloy coating on the surface of the matrix.

Matrix material: alloy steel

Constituent materials: Multi-coating: composite dual super alloy and ceramic dual alloy: mold steel and chromium-molybdenum alloy steel

Working principle diagram:

Perfect processing system: machining-shot blasting-spraying-finishing-inspection-shipment

Welcome To The Professional Manufacturer Of Thermal Spraying.

Share With You

-

19 Feb 2026

19 Feb 2026Abrasion Resistant & Corrosion Resistant Coatings for Wear-Resistant Bushings and Plungers

Understanding Abrasion Resistant and Corrosion Resistant Coatings Abrasion resistant coatings and corrosion resistant coatings are two of the most critical surf...

-

12 Feb 2026

12 Feb 2026Thermal Spray Coatings Guide: HVOF, Ceramic, and Tungsten Carbide Coating Solutions

What Is Thermal Spray and How Does the Process Work? Thermal spray is a group of industrial coating processes in which feedstock materials — supplied as powder,...

-

04 Feb 2026

04 Feb 2026Tungsten Carbide Coating Process: Complete Guide to Application Methods & Benefits

Understanding Tungsten Carbide Coatings Tungsten carbide coatings represent one of the most effective solutions for enhancing surface hardness, wear resistance,...

-

30 Jan 2026

30 Jan 2026What Is Abrasion Resistant Coating and When Should You Use It?

Understanding Abrasion Resistant Coating and Its Core Purpose Abrasion resistant coating is a surface treatment designed to protect substrates from mechanical w...

TOP

TOP

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体