- Description

- Contact Us

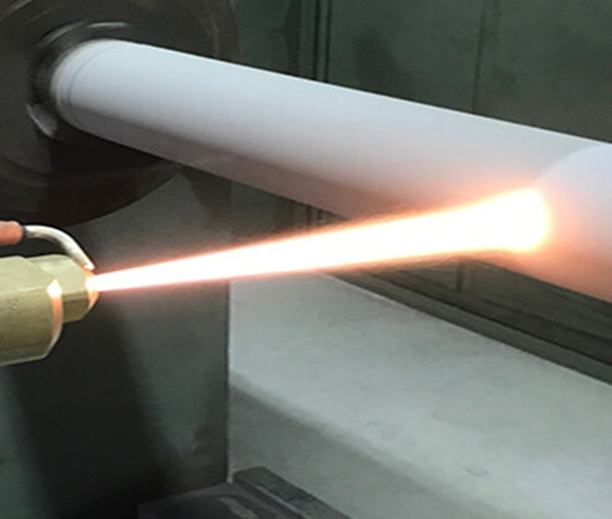

The Injection Sleeve Assembly is a vital component in the die casting process, designed to facilitate the injection of molten metal into molds. It serves to guide and protect the injection plunger during the high-pressure injection, ensuring smooth and efficient metal flow while preventing wear and damage to the injection system.

Manufactured from durable, high-strength materials such as heat-resistant alloys or specially treated steel, the Injection Sleeve Assembly is engineered to withstand the extreme pressures and temperatures encountered during the die casting process. Its precise design ensures accurate alignment of the injection system, contributing to consistent part quality and reduced cycle times.

The assembly includes the sleeve itself, along with supporting components such as seals, guides, and bushings, all of which work together to maintain the integrity of the injection mechanism and enhance the overall performance of the die casting machine. The use of advanced coatings or surface treatments can further enhance the sleeve's resistance to wear and corrosion, extending its operational life and reducing maintenance requirements.

Product advantages:

Using the same material and processing technology, quality packaging overall processing, precision, and matching to achieve the best state;

Reasonable punching and material tube clearance matching, extending life and improving injection accuracy;

Unified models, reducing inventory.

Specifications: 280T/400T/500T/800T

Welcome To The Professional Manufacturer Of Thermal Spraying.

Share With You

-

19 Feb 2026

19 Feb 2026Abrasion Resistant & Corrosion Resistant Coatings for Wear-Resistant Bushings and Plungers

Understanding Abrasion Resistant and Corrosion Resistant Coatings Abrasion resistant coatings and corrosion resistant coatings are two of the most critical surf...

-

12 Feb 2026

12 Feb 2026Thermal Spray Coatings Guide: HVOF, Ceramic, and Tungsten Carbide Coating Solutions

What Is Thermal Spray and How Does the Process Work? Thermal spray is a group of industrial coating processes in which feedstock materials — supplied as powder,...

-

04 Feb 2026

04 Feb 2026Tungsten Carbide Coating Process: Complete Guide to Application Methods & Benefits

Understanding Tungsten Carbide Coatings Tungsten carbide coatings represent one of the most effective solutions for enhancing surface hardness, wear resistance,...

-

30 Jan 2026

30 Jan 2026What Is Abrasion Resistant Coating and When Should You Use It?

Understanding Abrasion Resistant Coating and Its Core Purpose Abrasion resistant coating is a surface treatment designed to protect substrates from mechanical w...

TOP

TOP

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体