- Description

- Contact Us

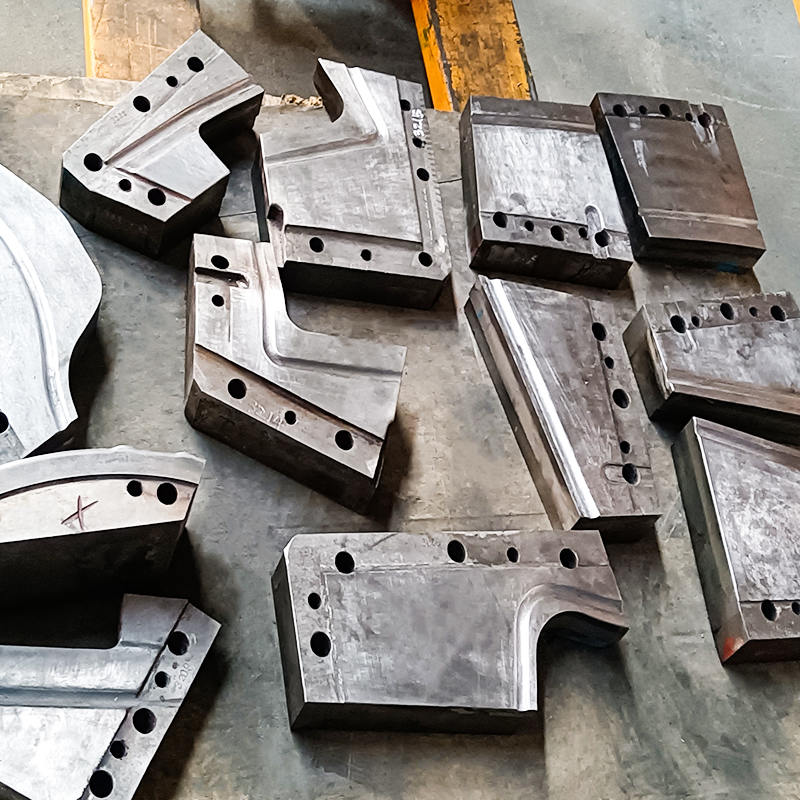

The Wear-Resistant Inlay Blocks for Stamping Dies are precision components designed to enhance the performance and service life of stamping molds used in the automotive industry and other high-volume sheet metal forming operations. These blocks are embedded into critical wear areas of the die to withstand repeated impact and abrasive contact during the stamping process.

To address the challenges of mold wear and deformation in sheet metal forming, the inlay blocks are manufactured from high-performance materials and treated with advanced thermal spraying technology. This surface treatment significantly increases the hardness, wear resistance, and corrosion resistance of the inlay surface without compromising the core toughness of the base material.

The treated inlay blocks exhibit improved properties such as:

High surface hardness

Low friction coefficient

Enhanced fatigue resistance

Stable dimensional performance under cyclic loading

These characteristics contribute to longer mold life, reduced maintenance frequency, and improved part quality in production. The inlay blocks can be customized to fit various die configurations and are suitable for both progressive and transfer die systems.

They are an effective solution for improving tool performance in automotive body panel production and other precision metal forming applications.

Welcome To The Professional Manufacturer Of Thermal Spraying.

Share With You

-

21 Jan 2026

21 Jan 2026Techniques and Materials Used in Ceramic Thermal Spray Coatings

Overview of Ceramic Thermal Spray Coatings Ceramic thermal spray coatings are advanced surface engineering solutions applied to protect metal, ceramic, or compo...

-

14 Jan 2026

14 Jan 2026What Is a Coated Shaft Sleeve and Why It Matters in Industrial Equipment

Understanding the Function of a Coated Shaft Sleeve A coated shaft sleeve is a protective cylindrical component installed over a rotating shaft to shield it fro...

-

07 Jan 2026

07 Jan 2026Abrasion Resistant Coating Basics Materials Performance and Uses

Understanding Abrasion Resistant Coating Fundamentals Abrasion resistant coating refers to a category of surface protection materials designed to reduce materia...

-

04 Jan 2026

04 Jan 2026Wear-Resistant Bushings vs Standard Bushings: What You Should Know

Introduction to Bushings Bushings are essential components in machinery, providing a bearing surface for rotary or sliding applications. They reduce friction, a...

TOP

TOP

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体