Content

- 1 The Role of Ceramic Thermal Spray Coatings in Thermal Resistance

- 2 What Are Ceramic Thermal Spray Coatings?

- 3 Improved Thermal Insulation and Heat Resistance

- 4 Protection Against Thermal Cycling and Thermal Shock

- 5 Enhancing Performance in High-Temperature Environments

- 6 Applications of Ceramic Thermal Spray Coatings in Manufacturing

- 7 Conclusion: The Value of Ceramic Thermal Spray Coatings in Manufacturing

The Role of Ceramic Thermal Spray Coatings in Thermal Resistance

In manufacturing, components and equipment often face high temperatures that can degrade their performance and shorten their lifespan. One of the most effective ways to enhance thermal resistance and protect surfaces from excessive heat is through the application of ceramic thermal spray coatings. These coatings provide superior heat insulation and protection against thermal stress, making them essential for industries dealing with extreme temperatures. In this article, we explore how ceramic thermal spray coatings improve thermal resistance and the benefits they offer to manufacturing processes.

What Are Ceramic Thermal Spray Coatings?

Ceramic thermal spray coatings are applied through a process where ceramic materials are heated to a molten state and then sprayed onto a substrate. The resulting coating forms a durable layer that enhances the surface's ability to resist heat, wear, and corrosion. These coatings are typically made from materials such as aluminum oxide, zirconia, and titanium oxide, all of which have excellent thermal resistance properties.

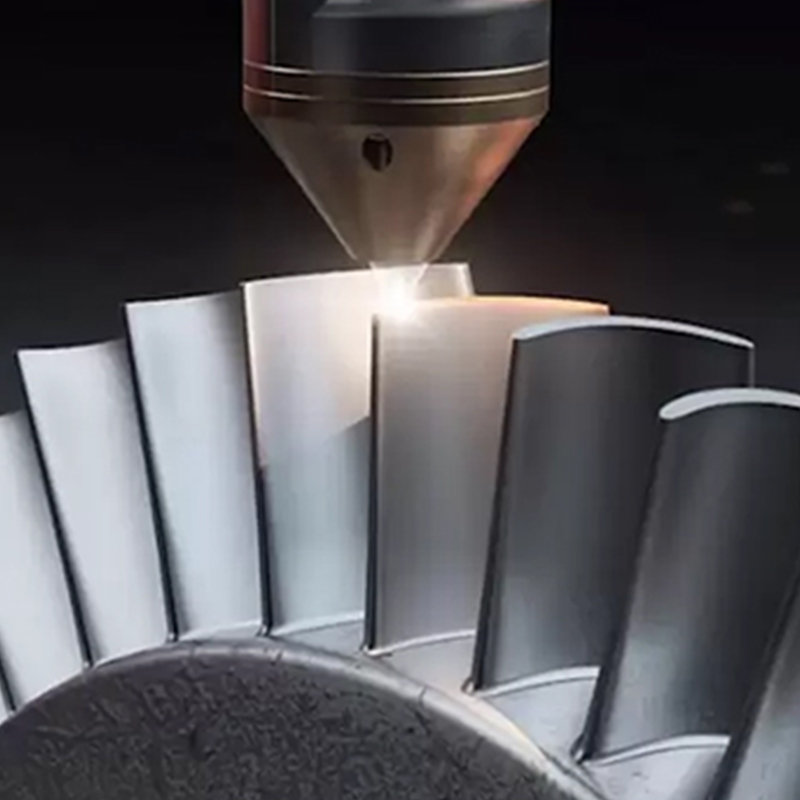

The thermal spraying process allows these ceramic materials to bond strongly to the substrate, creating a hard, protective layer that is highly effective in preventing heat damage. This makes ceramic thermal spray coatings particularly valuable for components exposed to high-temperature environments, such as in aerospace, automotive, and energy sectors.

Improved Thermal Insulation and Heat Resistance

One of the most significant advantages of ceramic thermal spray coatings is their ability to provide excellent thermal insulation. These coatings act as a barrier that prevents heat from penetrating the underlying material, thus reducing the temperature rise on critical components. This is especially important in applications where temperature fluctuations can cause material degradation or even failure.

Materials like zirconia are particularly known for their low thermal conductivity, which allows them to withstand and insulate against extreme heat. When applied to manufacturing components such as turbines, engine parts, and exhaust systems, ceramic thermal spray coatings help maintain optimal operating temperatures, improving the efficiency and longevity of these parts.

Key Thermal Resistance Benefits of Ceramic Thermal Spray Coatings

- Significant reduction in heat transfer, helping to protect sensitive components.

- Improved efficiency in high-temperature operations, preventing overheating.

- Increased lifespan of components by reducing thermal stress and wear.

Protection Against Thermal Cycling and Thermal Shock

Thermal cycling, where a component is exposed to repeated heating and cooling, can cause significant stress on materials, leading to cracking, warping, or premature failure. Ceramic thermal spray coatings are designed to withstand these thermal cycles, providing a protective barrier that helps absorb and dissipate thermal shock.

The thermal expansion properties of the ceramic coating differ from those of the underlying material, allowing the coating to absorb and distribute the heat more evenly. This reduces the risk of cracking or delamination that can occur in materials exposed to frequent temperature changes. The result is improved structural integrity and longer service life for manufacturing equipment.

Benefits of Ceramic Coatings for Thermal Cycling

- Enhanced resistance to cracking and deformation caused by rapid temperature fluctuations.

- Increased reliability of components exposed to high-temperature cycles.

- Minimized maintenance costs by extending the service life of parts.

Enhancing Performance in High-Temperature Environments

In industries such as aerospace, automotive, and power generation, equipment must perform reliably under extreme heat conditions. Ceramic thermal spray coatings are ideal for protecting parts in these high-stress environments, where even slight temperature increases can result in catastrophic failure. By providing superior thermal resistance, these coatings enhance the performance of parts in demanding applications like gas turbines, combustion chambers, and engine blocks.

The ability to withstand high temperatures without degrading or losing integrity allows parts to operate more efficiently, improving the overall performance of the machinery. In addition, these coatings prevent heat-related damage that could otherwise require expensive repairs or replacements.

High-Temperature Performance Benefits

- Protects critical components from heat-induced damage, extending their lifespan.

- Improves energy efficiency by maintaining optimal operating temperatures.

- Enhances overall system performance by reducing heat-related stress on equipment.

Applications of Ceramic Thermal Spray Coatings in Manufacturing

Ceramic thermal spray coatings are widely used in various manufacturing sectors to improve thermal resistance and protect against heat damage. Some of the most common applications include:

Aerospace and Aviation

- Turbine blades and exhaust systems exposed to high temperatures and thermal shock.

- Heat shields and other critical components requiring high thermal resistance.

Automotive

- Engine parts and exhaust systems exposed to high friction and heat.

- Turbochargers and other high-performance components requiring heat protection.

Energy and Power Generation

- Heat exchangers and components in power plants operating at extreme temperatures.

- Combustion chambers and other high-heat components that need to withstand thermal cycling.

Conclusion: The Value of Ceramic Thermal Spray Coatings in Manufacturing

Ceramic thermal spray coatings are a powerful tool for improving thermal resistance in manufacturing applications. They provide significant benefits in high-temperature environments by enhancing heat insulation, protecting against thermal cycling, and increasing the performance and lifespan of critical components. As industries continue to demand more from their equipment, ceramic thermal spray coatings offer a reliable, cost-effective solution for ensuring optimal performance in extreme conditions. For manufacturers seeking to protect their assets and improve efficiency, ceramic thermal spray coatings are an essential technology.

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体

TOP

TOP