Tungsten carbide coating has become an essential surface treatment for mining and oilfield equipment due to its exceptional hardness, wear resistance, and corrosion protection. In harsh industrial environments, components are exposed to abrasive materials, high pressures, and chemically aggressive fluids. Applying tungsten carbide coating extends the lifespan of critical machinery, reduces maintenance costs, and enhances operational efficiency.

Content

Mining Equipment Applications

In the mining sector, equipment such as drill bits, conveyors, excavator buckets, and crushers experience extreme wear from abrasive rocks and minerals. Tungsten carbide coatings provide a durable protective layer, significantly reducing material loss and extending service intervals. For drill bits, the coating enhances penetration rates and reduces downtime for replacement, improving overall productivity.

Crushers and grinding mills benefit from tungsten carbide coating on wear-prone surfaces, minimizing erosion and maintaining consistent particle size output. Conveyors and bucket components experience reduced abrasion, which lowers operational costs and enhances safety by preventing sudden equipment failures.

Oilfield Equipment Applications

Oilfield equipment operates under high pressure and exposure to abrasive sands, drilling mud, and corrosive fluids. Components such as pump plungers, valve seats, drill collars, and mud agitators can achieve longer service life with tungsten carbide coatings. The coating’s hardness resists erosion from sand-laden drilling fluids, while its chemical stability prevents degradation in harsh chemical environments.

In pumps and valves, tungsten carbide coatings maintain dimensional accuracy and sealing efficiency, reducing leakage and improving operational reliability. Drill collars and other downhole tools maintain surface integrity under extreme mechanical stress, enabling deeper and more efficient drilling operations.

Key Benefits in Mining and Oilfield Equipment

- Enhanced wear and abrasion resistance for prolonged component life

- Improved corrosion and chemical resistance in harsh environments

- Reduced maintenance frequency and associated downtime

- Optimized operational efficiency and reduced replacement costs

- Maintained dimensional stability and precision under mechanical stress

Comparison of Tungsten Carbide Coating Performance

The performance of tungsten carbide coatings can be quantified across key operational parameters to guide material selection for specific applications:

| Application | Primary Wear Factors | Coating Benefits | Typical Components |

| Mining | Abrasive rock, impact, erosion | Reduced abrasion, longer lifespan | Drill bits, crushers, buckets, conveyors |

| Oilfield | Erosion from sand-laden fluids, chemical attack | Corrosion resistance, dimensional stability | Pump plungers, valve seats, drill collars, mud agitators |

Application Techniques and Considerations

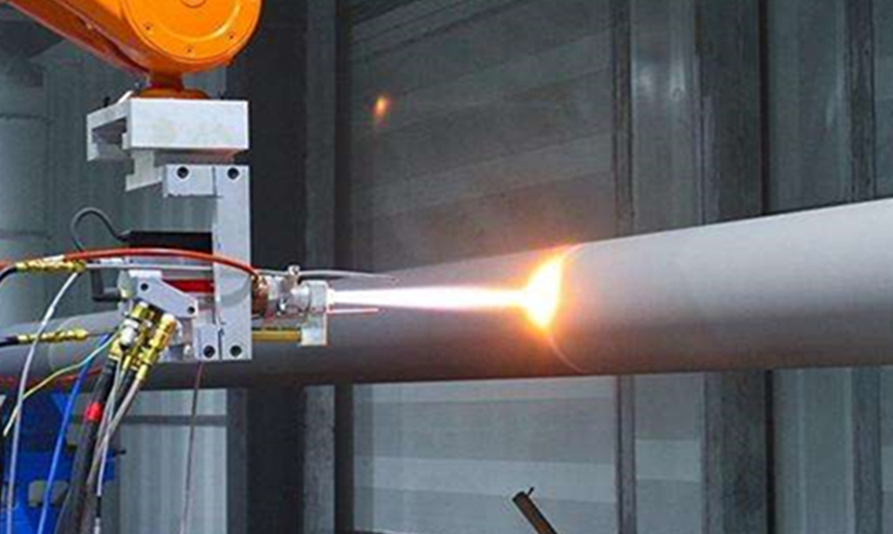

Tungsten carbide coatings can be applied using methods such as thermal spray, HVOF (High-Velocity Oxygen Fuel), and plasma spraying. Each method provides different thickness, adhesion, and surface finish characteristics suitable for specific equipment requirements. Choosing the appropriate application technique ensures optimal performance, minimizes coating defects, and maximizes component lifespan.

Surface preparation prior to coating, including cleaning, roughening, and priming, is critical to achieve strong adhesion. Post-coating inspection and testing, such as hardness measurement and thickness verification, confirm the quality and uniformity of the applied coating.

Conclusion

Tungsten carbide coating plays a vital role in extending the service life and reliability of mining and oilfield equipment. Its exceptional wear resistance, corrosion protection, and ability to maintain dimensional integrity under extreme conditions make it indispensable for critical industrial machinery. Proper selection of coating methods, surface preparation, and maintenance ensures maximum benefit, improving operational efficiency, reducing downtime, and lowering overall equipment costs.

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体

TOP

TOP