Content

- 1 Ceramic Thermal Spray Coatings in Industrial Corrosion Resistance Applications

- 2 Why Choose Ceramic Thermal Spray for Corrosion Resistance?

- 3 Common Ceramic Systems and Their Corrosion Performance

- 4 Practical Surface Preparation and Bonding Requirements

- 5 Application Methods: Choosing the Right Process

- 6 Inspection, Testing and Acceptance Criteria

- 7 Maintenance Strategies and Life-Cycle Considerations

- 8 Selection Checklist for Corrosion Applications

- 9 Conclusions and Practical Recommendations

Ceramic Thermal Spray Coatings in Industrial Corrosion Resistance Applications

Ceramic thermal spray coatings are a practical solution for protecting industrial assets from corrosion where conventional metallic coatings fail or are uneconomic. This article focuses on concrete, actionable guidance for engineers and maintenance teams: when to choose ceramic thermal spray, which ceramic systems suit different chemistries, how to prepare substrates and apply coatings to maximize corrosion resistance, and how to inspect and maintain coated equipment in the field. The emphasis is on industrial process environments — chemical plants, pulp & paper, power generation, desalination and offshore systems — where corrosion mixes with erosion, abrasion, and elevated temperature.

Why Choose Ceramic Thermal Spray for Corrosion Resistance?

Ceramic thermal spray coatings (including plasma-sprayed, flame-sprayed, and HVOF-applied ceramic composite overlays) provide a barrier that resists chemical attack, pitting, and localized corrosion. Unlike thin organic paints, ceramics provide hard, inert surfaces that maintain integrity in highly oxidative or acidic media and resist under-film degradation. They also tolerate high temperatures and offer good erosion-corrosion resistance when particulate or high-velocity fluids are present. The key advantages are chemical inertness, thermal stability, and mechanical toughness when applied as modern composite or graded layers.

Common Ceramic Systems and Their Corrosion Performance

Selecting the right ceramic formulation is critical. Below are common ceramic and ceramic-composite thermal spray materials and practical guidance on their corrosion characteristics in industrial environments.

Alumina (Al₂O₃) and Stabilized Alumina

Alumina is widely used for chemical resistance and electrical insulation. It performs well against acids and many neutral aqueous solutions but may be vulnerable to alkali attack at high temperatures. Dense, properly bonded plasma-sprayed alumina layers form an effective barrier against chloride-induced pitting on steel substrates when combined with a suitable bond coat to prevent oxygen ingress.

Chromia and Spinel-Based Ceramics

Chromia (Cr₂O₃) and spinel ceramics (e.g., MgAl₂O₄ or NiAl₂O₄-based formulations) offer improved chemical stability in oxidizing and chloride-containing environments compared with pure alumina. They are commonly used where slightly higher corrosion resistance and thermal stability are required, such as in flue gas desulfurization (FGD) and high-temperature process lines.

Ceramic-Metal (Cermet) Overlays

Cermets combine ceramic phases (alumina, chromium oxide, titania) with metallic binders (NiCr, CoNi) delivered by HVOF or plasma spray. The metal phase improves toughness and adhesion while the ceramic phase provides corrosion resistance. Cermets excel where erosion-corrosion is present — for example pump casings and ductwork conveying particulate-laden fluids — and they allow for better machinability of coated surfaces for tolerance-critical components.

Zirconia and Stabilized Zirconia

Zirconia-based coatings (often yttria-stabilized zirconia) are chosen for thermal barrier performance and chemical inertness at elevated temperature. For corrosion resistance, zirconia is effective in oxidizing environments and can be combined with alumina or cermet layers to resist specific chemical attacks. Zirconia is less commonly used alone for aqueous corrosion unless thermal stability is the primary concern.

Practical Surface Preparation and Bonding Requirements

Coating performance depends heavily on substrate preparation and bond integrity. Poor preparation leads to under-film corrosion and delamination. Follow these practical steps to ensure long-term corrosion resistance.

Mechanical Abrasive Blasting

Abrasive blasting to a near-white or commercial-blast finish (Sa2.5 or Sa2, per ISO 8501) removes oxides and creates a uniform anchor profile. For steels, target a 50–100 µm peak-to-valley profile depending on coating thickness; too shallow reduces adhesion, too rough traps moisture under the coating.

Use of Bond Coats and Tie Layers

Apply a metallic bond coat (e.g., NiCr, MCrAlY) when coating steels to block diffusion of oxygen and salts and to improve adhesion. For dissimilar substrates (stainless to carbon steel), a transitional bond coat or gradient layer reduces thermal expansion mismatch and the risk of cracks that permit corrosive ingress.

Control of Porosity and Microcracks

Thermal spray inherently produces some porosity and microcracking. Minimize open porosity by selecting the appropriate spray process (HVOF yields denser cermet coatings than atmospheric plasma spray) and by post-seal treatments. After-spray impregnation or sealing with low-viscosity polymers or silicates reduces pathways for corrosive species while retaining the ceramic's mechanical properties.

Application Methods: Choosing the Right Process

Different thermal spray processes produce coatings with differing density, bond strength and residual stress. Match the process to the corrosion and mechanical demands of the service.

HVOF (High-Velocity Oxy-Fuel) for Dense Cermets

HVOF produces dense, low-porosity cermet coatings with excellent adhesion and resistance to erosion-corrosion. Use HVOF for pump internals, pipe elbows, valve seats and other high-velocity, particulate-exposed surfaces where both corrosion and mechanical wear occur.

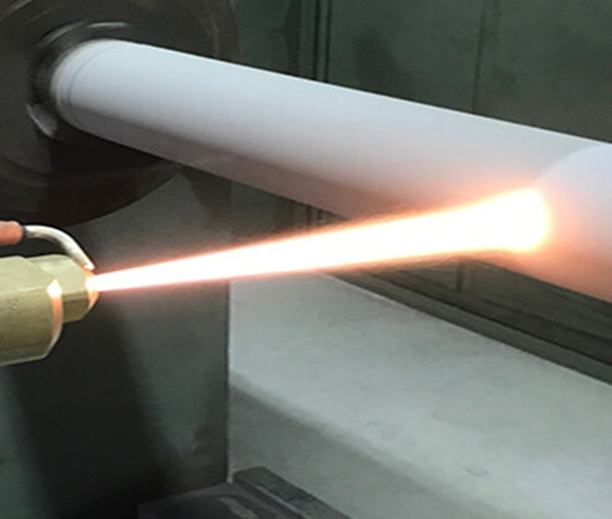

Plasma Spray for Thick Ceramic Barriers

Atmospheric plasma spray (APS) is suitable for applying thick ceramic layers like alumina in chemical tanks and ducts. APS allows high deposition rates but often results in higher porosity than HVOF; sealing or post-treatments are recommended for aqueous corrosion environments.

Cold Spray and Detonation Gun (D-Gun) Options

Cold spray can deposit metallic bond coats without oxidation, preserving ductility. D-gun processes deliver high-velocity deposits with unique microstructures; they can be useful for certain cermets where extreme adhesion and low porosity are required. Consider these methods where substrate heat sensitivity or oxidation control is important.

Inspection, Testing and Acceptance Criteria

Robust inspection regimes verify corrosion protection before commissioning and during service. Practical tests and acceptance thresholds include bond strength, porosity, and accelerated corrosion testing.

- Adhesion testing—pull-off or bend tests to confirm manufacturer-specified bond strength, typically >30 MPa for critical applications.

- Porosity measurement—use image analysis on cross-sections or mercury intrusion methods; targets vary by process but aim for <2–5% open porosity for aqueous corrosion environments.

- Salt spray and immersion trials—perform accelerated exposure (e.g., ASTM B117 or immersion in representative process liquor) on test coupons to identify blistering, undercutting or chemical attack before full-scale application.

- Thickness and visual uniformity—verify coating thickness with nondestructive gauges; typical protective ceramic layers range from 100 µm (thin cermet) to 1 mm or more (barrier ceramics), depending on service.

Maintenance Strategies and Life-Cycle Considerations

Ceramic coatings extend asset life, but planning for inspection and repair is essential for cost-effective life-cycle management. Focus on sealing integrity, localized damage, and reapplication protocols.

Regular Condition Monitoring

Schedule visual checks for cracking, spallation, or deposits. Use ultrasonic thickness checks where applicable to detect substrate loss under coatings and monitor for delamination signs using tap tests or acoustic emission methods.

Localized Repair Techniques

Small damaged areas can often be repaired by grinding to a clean profile, reapplying a bond coat and re-spraying the ceramic. For extensive damage, consider stripping and full recoat. Keep spare coated coupons and process parameters documented to ensure consistent repairs.

Selection Checklist for Corrosion Applications

| Question | Practical Action |

| What is the operating chemical environment? | Select ceramic chemistry resistant to acids/alkalis; prefer cermets if particulates present. |

| Are high velocities or particulates present? | Choose HVOF-deposited cermets or HVOF + WC overlays for erosion-corrosion. |

| Is substrate heat sensitivity a concern? | Consider cold spray for bond coats or low-heat processes; minimize thermal input. |

| What are inspection and repair capabilities? | If field repairs are limited, prefer robust, low-porosity HVOF coatings with sealing. |

Conclusions and Practical Recommendations

Ceramic thermal spray coatings are a powerful tool in the corrosion engineer’s toolbox when selected and applied with practical constraints in mind. For aqueous chloride or acidic services with mechanical wear, prefer dense cermet HVOF overlays with a metallic bond coat and post-seal. For large-area barrier needs where high-temperature stability is required, plasma-sprayed alumina or chromia layers with sealing can be effective. Always verify coating performance with representative coupon tests, adhere to rigorous surface preparation standards, and plan for routine inspection and localized repairs. These steps ensure ceramic thermal spray systems deliver measurable reductions in corrosion-related downtime and maintenance cost.

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体

TOP

TOP