High-Velocity Oxygen Fuel (HVOF) thermal spray technology has become a critical solution in surface engineering and industrial coatings. HVOF thermal spray processes offer superior wear, corrosion, and heat resistance, extending the service life of components across diverse industries. From aerospace and automotive to energy production and manufacturing, HVOF coatings are widely recognized for their dense, high-performance surfaces.

Content

Understanding HVOF Thermal Spray

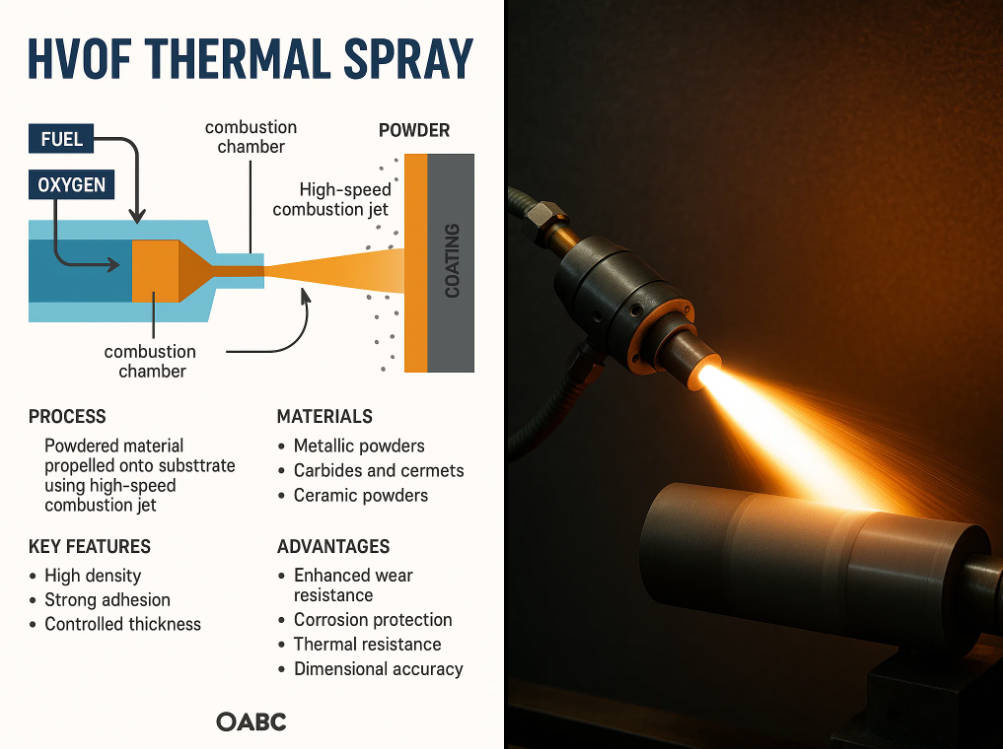

HVOF is a high-velocity, high-temperature coating process that propels powdered materials onto a substrate using a high-speed combustion jet. The process involves mixing fuel and oxygen, which is ignited in a combustion chamber. The generated high-pressure gas accelerates the powder particles toward the target surface at supersonic speeds, forming a dense and well-bonded coating.

Key features of HVOF coatings include:

- High density and low porosity, improving wear and corrosion resistance.

- Strong adhesion to substrates, ensuring long-lasting performance.

- Controlled thickness and uniform deposition, suitable for precision components.

HVOF coatings can be applied to metals, alloys, ceramics, and composite surfaces, providing tailored protection depending on operational requirements.

Materials Commonly Used in HVOF Thermal Spray

HVOF coatings use a variety of powders to meet different application needs:

- Metallic Powders: Nickel, cobalt, and chromium alloys offer excellent corrosion and oxidation resistance.

- Carbides and Cermets: Tungsten carbide (WC), chromium carbide (CrC), and cobalt-based cermets provide superior wear resistance in abrasive environments.

- Ceramic Powders: Oxides like alumina or zirconia enhance thermal barrier performance, suitable for high-temperature applications.

The choice of powder material is critical to achieving the desired surface properties, including hardness, friction reduction, and resistance to chemical attack.

Advantages of HVOF Thermal Spray

-

Enhanced Wear Resistance

HVOF coatings provide a dense and hard surface that protects components from abrasion, erosion, and impact wear. This is particularly valuable in industrial machinery, pumps, and turbines. -

Corrosion Protection

By creating a tight, low-porosity coating, HVOF reduces exposure to corrosive environments, extending the lifespan of parts in chemical processing, marine, and energy industries. -

Thermal and Oxidation Resistance

HVOF coatings can withstand high temperatures and prevent oxidation, making them ideal for gas turbines, engine components, and exhaust systems. -

Dimensional Accuracy and Surface Quality

Unlike other coating methods, HVOF allows precise control over thickness, roughness, and surface profile, which is essential for components that require tight tolerances. -

Cost and Performance Efficiency

Extending the service life of components reduces maintenance costs and downtime. HVOF thermal spray is often more cost-effective than replacing or machining parts repeatedly.

Applications of HVOF Thermal Spray

HVOF coatings are widely applied across multiple industries:

- Aerospace: Turbine blades, landing gear, and engine components benefit from wear and heat-resistant coatings.

- Automotive: Engine parts, fuel injectors, and transmission components gain enhanced durability.

- Energy and Power Generation: Gas turbines, steam turbines, and industrial pumps receive improved wear and corrosion protection.

- Mining and Metallurgy: Rollers, dies, and other wear-prone equipment achieve longer operational life.

- Oil and Gas: HVOF coatings protect components exposed to corrosive fluids and abrasive materials.

The process can be adapted for both large-scale industrial production and small precision components, making it a versatile solution for engineering challenges.

Innovations and Future Trends

Recent developments in HVOF thermal spray include:

- Nanostructured coatings: Enhancing hardness and wear resistance at the nanoscale.

- Automated HVOF systems: Improving consistency, speed, and precision in high-volume applications.

- Hybrid coatings: Combining metals, carbides, and ceramics to optimize both wear and corrosion resistance.

Additionally, integration with additive manufacturing and surface engineering techniques is opening new opportunities for HVOF coatings in customized, high-performance components.

Conclusion

HVOF thermal spray technology provides high-performance, durable, and versatile coatings that address the demanding requirements of modern industrial applications. Its ability to deliver dense, low-porosity surfaces with excellent adhesion and wear resistance makes it indispensable in aerospace, automotive, energy, and manufacturing industries.

By extending component life, reducing maintenance costs, and enhancing operational reliability, HVOF thermal spray represents a key solution in surface engineering, driving innovation and performance in critical industrial sectors.

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体

TOP

TOP