In modern manufacturing and heavy industries, protecting components from wear, corrosion, and high temperatures is critical. HVOF (High Velocity Oxy-Fuel) thermal spray has emerged as one of the most effective methods for producing high-performance coatings that improve durability and extend service life. This technology is widely used across aerospace, oil and gas, power generation, and metal processing industries.

Content

Understanding the HVOF Process

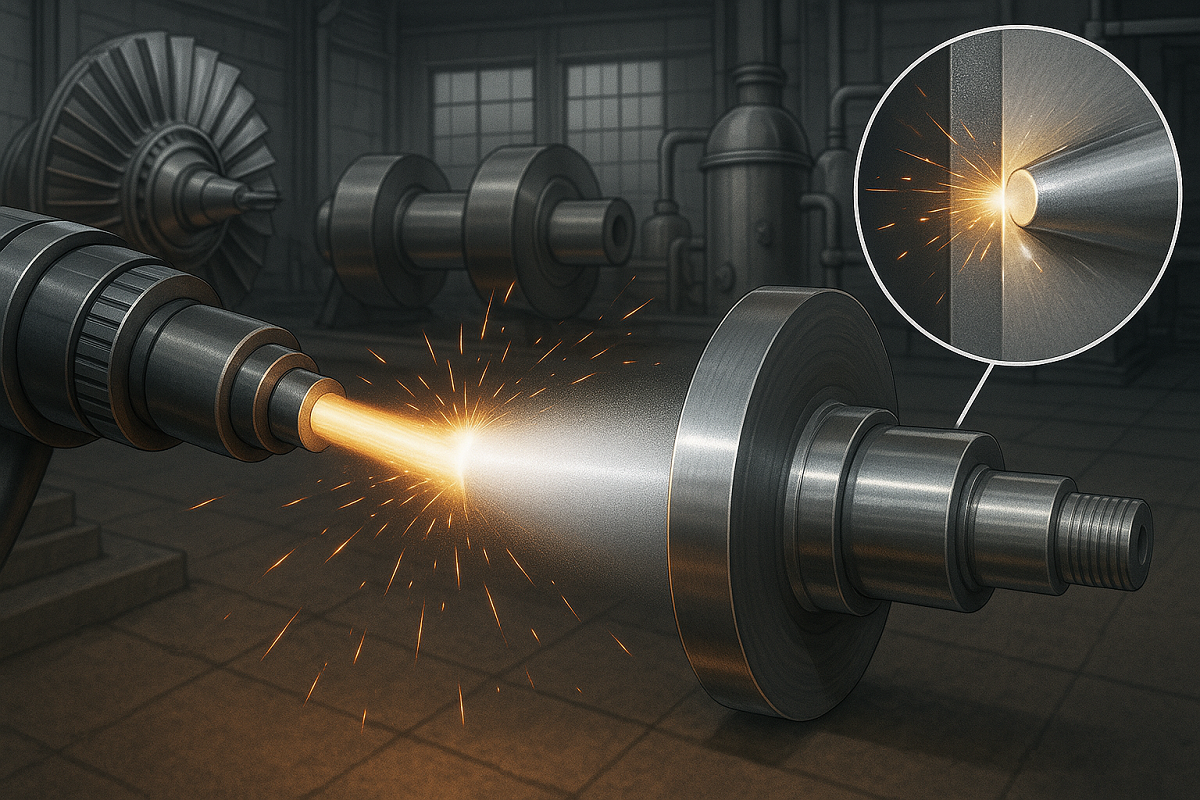

HVOF thermal spraying involves a combustion-driven process where oxygen and fuel gases—such as hydrogen, propane, or kerosene—are ignited to create a supersonic jet. Powdered coating material, including metals, alloys, or carbides, is injected into this jet and propelled at extremely high velocities toward the substrate.

Unlike traditional flame or plasma spraying, HVOF maintains lower operating temperatures while achieving particle velocities often exceeding 600–1000 m/s. This results in coatings that are dense, strongly bonded, and low in porosity, making them ideal for challenging industrial environments.

Benefits of HVOF Coatings

Exceptional Wear Resistance

The high kinetic energy of particles in HVOF ensures uniform, dense coatings that resist abrasive wear, erosion, and surface fatigue. Materials such as tungsten carbide-cobalt (WC-Co) or chromium carbide offer excellent hardness and durability, which is critical for components like pump impellers, rollers, and turbine blades.

Strong Adhesion and Low Porosity

HVOF coatings achieve superior mechanical and metallurgical bonding with substrates, resulting in extremely high adhesion strength. Low porosity (<1%) minimizes the risk of corrosion and ensures long-lasting performance in harsh environments.

Improved Corrosion and Oxidation Protection

Metal and alloy coatings applied via HVOF, such as Inconel or stainless steel, provide excellent resistance to chemical corrosion and high-temperature oxidation. This is particularly beneficial for oilfield equipment, heat exchangers, and gas turbines.

Cost Savings and Extended Component Life

By restoring worn parts and protecting new components, HVOF reduces the frequency of replacement and maintenance costs. This translates to less downtime, improved productivity, and more efficient resource utilization.

Applications Across Industries

HVOF thermal spray finds applications in a wide range of sectors:

- Aerospace: Landing gear, turbine blades, and hydraulic components benefit from wear and corrosion resistance.

- Oil and Gas: Valves, drill collars, and pump parts are protected from abrasive slurries and corrosive fluids.

- Power Generation: Boiler tubes, turbine shafts, and compressor components maintain performance under extreme temperatures.

- Metalworking and Paper Industries: Rolls, dies, and molds gain extended life and consistent surface quality.

The technology’s versatility allows it to meet the needs of components exposed to high mechanical stress, chemical attack, or thermal cycling.

Key Considerations for HVOF Coating

Surface Preparation

Proper preparation, such as grit blasting or cleaning, is essential to ensure optimal adhesion and coating density.

Process Control

Critical parameters include fuel-to-oxygen ratios, spray distance, and powder feed rates. Maintaining precise control ensures consistent coating quality.

Quality Inspection

Techniques like bond strength testing, porosity measurement, and microstructural analysis confirm that coatings meet industrial specifications and performance requirements.

Emerging Innovations

Recent developments are enhancing HVOF technology further:

- Suspension HVOF (S-HVOF) for finer microstructures and smoother coatings.

- Robotic and automated systems for complex geometries and high repeatability.

- Hybrid processes combining HVOF with plasma or cold spray to optimize performance.

These innovations expand the scope of HVOF applications and improve coating precision for high-value and critical components.

Conclusion

HVOF thermal spray is a proven solution for enhancing component durability and performance in industries where wear, corrosion, and thermal stress are concerns. Its ability to produce dense, adherent, and high-strength coatings allows manufacturers to extend the service life of critical parts while reducing maintenance costs. With ongoing technological advancements, HVOF continues to offer reliable, high-performance surface protection for modern industrial applications.

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体

TOP

TOP