We are pleased to unveil our newly developed Gear Pump Accessories Series, designed to meet the evolving needs of modern industrial pumping systems. This lineup features three key components: the Gear Pump Idler Pin (Coated Pin), Gear Pump Rotor Axis (Coating Rotor Axis), and Gear Pump Bushing (Coated Bushing). Each product in this series reflects our commitment to precision engineering, durability, and technological advancement through the use of protective surface coatings.

Content

Engineered for Long-Term Performance

In gear pump applications, internal components are subject to constant rotational stress, fluid pressure, and environmental challenges such as temperature fluctuations, moisture, and abrasive materials. Over time, these factors can lead to increased wear, reduced efficiency, and higher maintenance demands.

Our new accessories are developed specifically to combat these issues. With carefully selected materials and a high-performance coating process, each part delivers enhanced resistance to wear, corrosion, and mechanical fatigue — helping extend the operational life of the entire pump assembly.

Product Overview and Technical Highlights

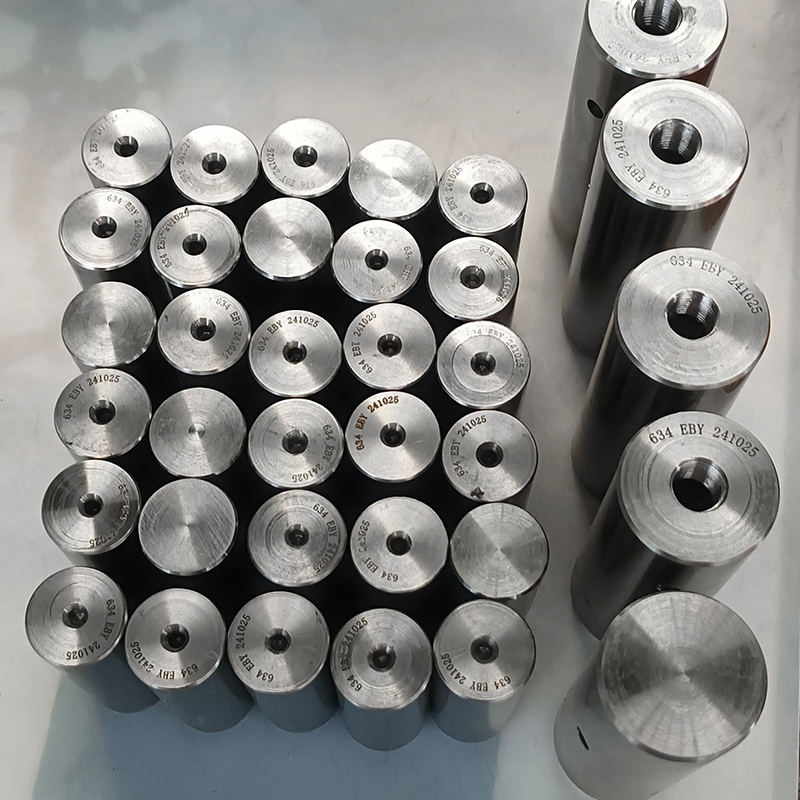

1. Gear Pump Idler Pin (Coated Pin)

The idler pin functions as a stationary shaft that supports the driven gear in a gear pump. Its job is critical to the alignment and rotational balance of the gear set. Our coated idler pin is manufactured with high-grade alloy steel and finished with a wear-resistant surface treatment. This coating improves hardness and sliding characteristics, making the pin suitable for heavy-duty conditions and long service intervals.

- Surface hardness improved by over 30%

- Better load distribution with precision tolerance

- Excellent corrosion resistance in oil and water environments

- Suitable for gear pumps used in lubrication, oil transfer, and hydraulic systems

2. Gear Pump Rotor Axis (Coating Rotor Axis)

The rotor axis is the central rotating shaft that drives the pumping action. It must operate reliably under torque stress and continuous motion. Our rotor axis is precisely machined and coated to minimize surface friction and improve thermal stability during extended operation. The result is a more stable gear mesh with less vibration and noise.

- Smooth surface finish to reduce internal drag

- High concentricity ensures balanced rotation

- Coated to resist micro-abrasion and pitting

- Compatible with high-viscosity fluids and high-pressure systems

3. Gear Pump Bushing (Coated Bushing)

The bushing is a key wear part that serves as a bearing surface within the pump housing. Our coated bushing is optimized for both oil-lubricated and dry-running conditions. The surface treatment reduces start-up wear and prevents galling or seizure during intermittent operation.

- Low-friction coating reduces energy consumption

- Enhanced support for shaft alignment and stability

- High dimensional accuracy for easy installation

- Extended service life in continuous and stop-start applications

Industrial Applications

The Gear Pump Accessories Series is developed with broad compatibility in mind, making it suitable for integration into a variety of pump systems used in the following industries:

- Hydraulic Systems: Excavators, presses, and injection molding machines

- Lubrication Equipment: Engine oil distribution systems, industrial machinery

- Chemical Transfer Pumps: Solvent, acid, and base transfer operations

- Food and Beverage Pumps: When customized with food-grade coatings

- Petrochemical Processing: High-pressure circulation and metering applications

Whether installed in a high-speed gear pump or a low-speed positive displacement pump, these components contribute to a stable, low-maintenance pumping process. Their precision manufacturing and surface treatment processes are designed to reduce wear rates, improve start-up smoothness, and support longer maintenance cycles.

Coating Technology: Benefits That Go Beyond Protection

The coatings applied to the idler pins, rotor axes, and bushings go beyond simple protection. They are engineered to improve every performance parameter that matters in industrial operations. Benefits include:

- Reduced Downtime: Minimized component degradation means less frequent replacement.

- Improved Efficiency: Lower friction translates into reduced energy loss.

- Consistent Output: Maintains pump performance over extended periods without degradation.

- Operational Safety: Reduced risk of component failure in mission-critical applications.

Our proprietary surface coating process involves thermal or chemical bonding methods depending on material requirements. This ensures optimal adhesion and longevity even under extreme mechanical or thermal conditions.

Manufacturing Excellence and Quality Control

All components in the Gear Pump Accessories Series are manufactured in a controlled environment with strict adherence to ISO-certified processes. From raw material selection to final inspection, every stage is subject to rigorous quality checks, including:

- Surface roughness testing

- Dimensional verification using coordinate measuring machines (CMM)

- Coating adhesion and thickness testing

- Functional testing in simulated load conditions

This allows us to deliver parts that meet or exceed OEM specifications and are ready for direct installation or system retrofitting.

Flexible Supply Options and Customization

We understand that gear pump systems can vary significantly depending on industry, pressure rating, or fluid type. That’s why we offer multiple standard sizes and accept custom specifications. Whether you require an idler pin for a compact gear pump or a rotor axis for a high-capacity industrial unit, we can produce and deliver with short lead times.

Custom services include:

- Material substitution (e.g., stainless steel, bronze)

- Special coatings (PTFE, DLC, ceramic)

- Dimensional customization for legacy systems

- OEM or private label production

Partner with Us for Long-Term Value

The launch of this new accessories line marks our ongoing commitment to supporting pump users and OEMs with high-quality components that offer real-world performance advantages. We aim to be more than just a supplier—we strive to be a trusted partner in your system reliability and production efficiency.

To learn more about our Gear Pump Accessories Series or to request detailed product specifications and pricing, please contact our technical sales team or visit our official website.

ENG

ENG

English

English عربى

عربى Español

Español 中文简体

中文简体

TOP

TOP